After much searching, he would end up working designing landing gear for various fighter aircraft for Kawanishi Aircraft. The most striking of his works would be the Kawanishi Baika project, an aircraft powered by a pulsejet engine, itself a flying bomb, designed to explode on impact, and created to be flown by the famous "kamikaze" pilots of the Japanese Empire.

Scale model of the Kawanashi Baika that Yamamoto worked on, photo via Wikipedia by Gaijin - CC BY-SA 3.0 license via Wikimedia Commons.

At the end of the war, Yamamoto found a devastated country. Yamamoto had a house in Hiroshima, which after the war was found to be in perfect condition, rather odd given the circumstances of the atomic bomb that had fallen not far from there. Out of work at Kawanishi Aircraft, he decided to seek employment at Toyo Kogyo (Mazda, if you recall). Yamamoto admits that for him it was not a gamble of passion, but a solution to his difficult personal situation.

There was hardly any work, let alone for an engineer with only a few years of experience, all of which was in aviation. In any case, Toyo Kogyo offered him a job on the MazdaGo tricycle/motorcycle gearbox assembly line.

Mazda CT with Yamamoto-designed engine

Bored by the routine of the job, Yamamoto was genuinely depressed. In the midst of his repetitive daily routine, he came across some drawings of the gearboxes and differentials he was assembling on his production supervisor's desk, and asked for permission to examine them. From that day on, Yamamoto spent a year diligently checking the tolerances of the components and assemblies he was diligently assembling, improving production and the quality of the gearboxes that passed through his hands, until an engineer in the design department caught him red-handed and decided that Yamamoto's talent and desire to work meant that he deserved a position in the engineering department.

There he would be tasked with improving the twin-cylinder engines used in the MazdaGo, which still made use of a side-valve system. Yamamoto visited several motorcycle shops where old British engines were available, until he came across the cylinder head of a Triumph parallel twin-cylinder with overhead valves. He took this as inspiration and applied it to the design of a new cylinder head for the Toyo Kogyo engine that would power the new MazdaGo CT motorbike, which was an immediate commercial success.

This brought Yamamoto to the company, and allowed him to play an active role in the development of the original R360 Coupe, as well as its twin-cylinder engine, in 1959.

Mazda R360 Coupe

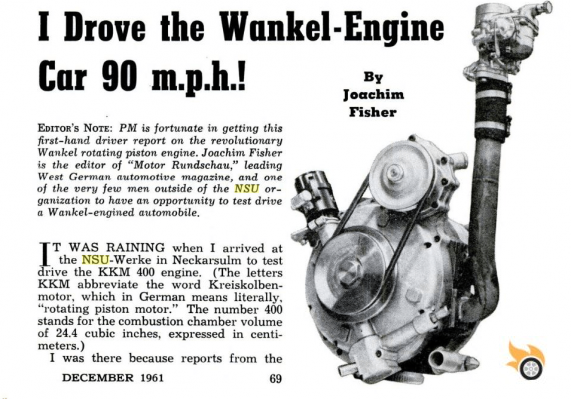

As we told you in a previous installment, Mazda decided at that time to join the Wankel engine bandwagon. NSU had organized a symposium in 1960 to explain the advantages of the engine and the conditions of a potential license, a license that Tsuneji Matsuda and four other technicians of the company, would consider interesting and in the end they would obtain for Toyo Kogyo.

Months later NSU would deliver the plans and a KKM 400 rotary engine to Hiroshima. The Japanese technicians would disassemble the engine piece by piece before reassembling it and creating an exact copy which they installed for 200 hours of testing, at which point it failed.

A subsequent disassembly discovered the marks left on the trochoid or stator body by the rotor showed where the problem was. This problem would be the one that many companies would consider impossible to solve, and they would refuse to produce motors even though they had acquired the license. But Toyo Kogyo wanted the engine to work. If it were to work, it would serve as the company's best advertising gimmick, giving it a competitive advantage.

Matsuda called the young Yamamoto to his office, and instructed him to organize a small development group, consisting of 47 engineers who would work from 1962 onwards in a dedicated facility, with Yamamoto often working from home "to experience the project and solve the problems". In 1964, the team of 47 engineers also received as a prize their own facilities, with computers and 20 test benches to keep the engines running 24 hours a day, covering kilometres.

Finally, after 5,000 destroyed engines testing different solutions, Yamamoto and his team came up with two key solutions: A special radial seal made of aluminum, and a chromed trochoid. Both combined avoided the problem of rotor tip marks on the stator, and ensured the reliability of the engine.

NSU KKM 400 engine, as shipped to Mazda

Thus, in 1967 the Mazda Cosmo Sport arrived on the market, the first twin-rotor rotary engine car on the planet, ahead of NSU's own Ro80 by several months, and with reliability issues completely solved. One of the key parts of the success of the Yamamoto-led project was that Mazda was the only company that had experience of making its own machine tools, so it could produce the complex shapes required by the Wankel engines.

Yamamoto's success led to Mazda's commitment to rotary engines, which would later prove almost catastrophic, as we told you, with the oil crisis, but Yamamoto would be instrumental once again in reinventing the Wankel engine as the heart of the RX-7 sports car saga. His perseverance to keep the Wankel engine active did not come at the expense of other engineering assignments, as he was the "father" behind the first 323 and 626.

Yamamoto would also be instrumental in the creation of the first 323 and 626.

By 1984, Yamamoto would become president of the company, and would be instrumental in the decision to set up a factory in the United States to reduce the costs of selling cars in that market and increase profits. As early as 1985, Yamamoto saw clearly that the market would gradually polarize between "low-cost generalist" products for emerging markets and people with no interest in owning a technological car, and another branch of more "premium and technological" products, which Mazda had to focus on, as he told the New York Times at the time.

In 1987, at the age of 62, Yamamoto became "ambassador and advisor to Mazda", leaving the presidency. His presence would be key, however, in the development of the MX-5 project, the Miata or whatever you want to call it. As Nobihiro Yamamoto would later acknowledge, Kenichi had laid "the seed" of the project for the Miata to be born.

His last great legacy at Mazda before retiring was the Miata, which he conceptualized in 1979.

In 1979 Kenichi had been talking to an American journalist about "the inexorable death and demise of the traditional fun-to-drive roadster", referring to the Lotus Elan and the British convertibles that would follow. Yamamoto's rise to the presidency of the company would solve that problem with a product that is still a commercial success today.

In 1992, at the age of 70, Yamamoto would retire, seeing his dream of creating the Miata come true, and having contributed to the automotive world with the development of the Wankel engine and the products that fitted it. A spectacular career that undoubtedly influenced all the technicians who began their careers under Yamamoto, and received that dose of DNA about "the way things are done" at Mazda.

A tribute to Mazda and its sporting and technological heritage