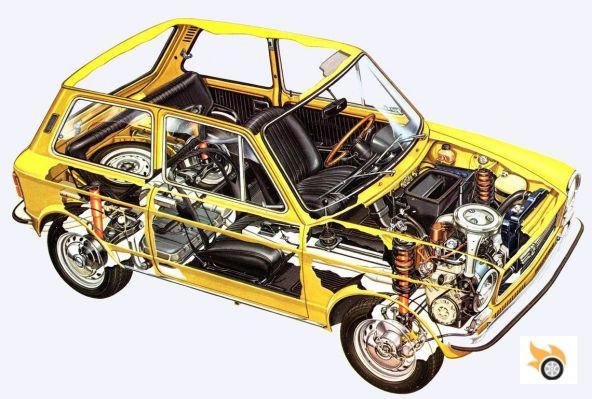

There is a lot of talk about electrification, autonomous driving and connected cars but these "news" seem to shift attention to the fact that we are still talking about vehicles that move on wheels along roads open to the public. We therefore always have a powertrain, a chassis with relative suspensions, braking and steering systems, interior furnishings and the essential (and particularly important for us at Pistonudos.com.it) active and passive safety systems. Among the latter, we cannot fail to mention the body which, with its reinforcements and programmed deformation zones, plays a leading role in limiting the consequences of accidents (see the crash tests of the very small but robust Smart). News arriving from the USA now allows us to peek under the skin of the most awaited electric car in recent years: the Tesla Model 3.

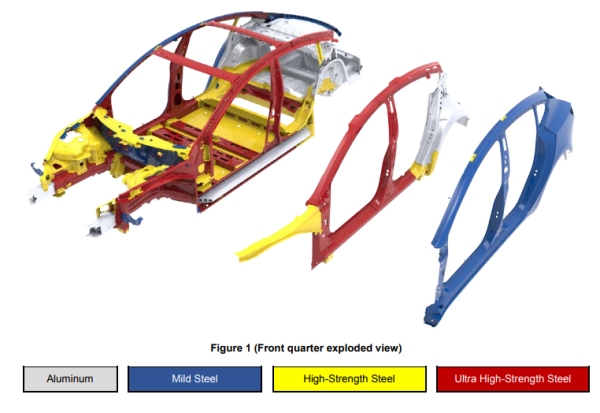

RED SAYS: ULTRA The outside of the side, including the door surround, is in normal steel (highlighted in blue) and has the task of absorbing the initial impacts. It mates with an internal structure, similar in shape, made of the same material: ultra-strong steel. In this way the A-pillar (the pillar of the windscreen) and the B-pillar (the central pillar), count on 3 layers, 2 of which in ultra-strong steel.

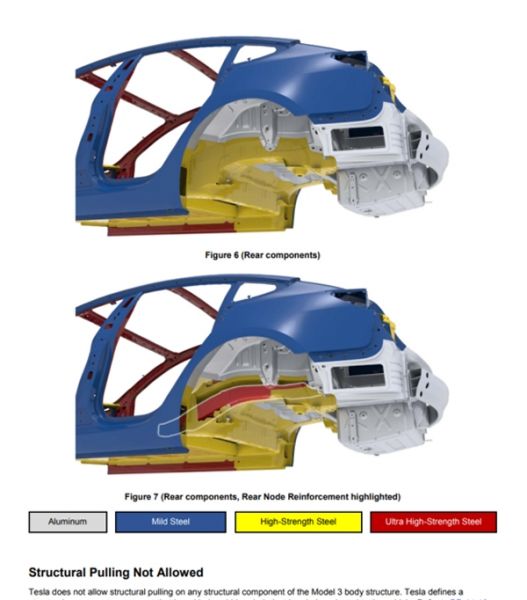

The protection against side impacts and rollovers (the roof cross members are also made of high-strength steel) should therefore be quite good. The Model 3 front upper spar also features a mixed construction with a high-strength steel exterior and an ultra-high-strength interior; it is the main support for the front crumple zone. In one of the illustrations it is explicitly indicated that "Structural Pulling is not allowed", i.e. it is not possible to bring back to the correct dimensions, with the classic template benches and hydraulic hoists/jacks, any structural component that is welded, welded and glued, riveted or riveted and glued. The reason for this prohibition is that in this way the resistance to deformation of the metals used would be compromised (read that every crashed car needs personalized repair procedures).

ALUMINUM WHERE IT'S NEEDED In the bottom view, we note that the entire lower part of the Model 3 is made of high-strength steel (indicated in yellow) and the main housings for the battery are visible (whose pack is defined in skateboard style: let's not forget that Tesla was born in Silicon Valley), similar to those used in the Model S and X.

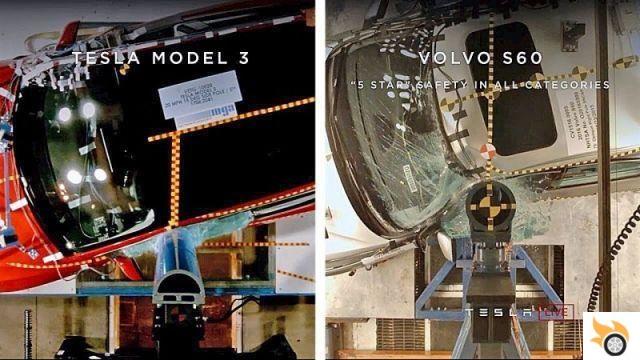

Lastly, light aluminum alloys (indicated in grey) are used in areas of the body less subject to major impacts, such as the floor of the boot and the wheel arches of the rear wheels, as well as a reinforcing crosspiece in the sill (laws of the alloy of easily recyclable aluminum used by Jaguar Land Rover). The use of aluminum helps Model 3 achieve a relatively light curb weight: 3.549 lbs (1.609 kg) for the standard version and 3.814 lbs (1.730 kg) for the extended range, thus featuring a larger and heavier battery (read that Toyota light cars will cost more for aluminum). We conclude with a curiosity: during the presentation of the Model 3, the video of a crash test (side impact against a pole) was presented in comparison with a Volvo S60: the "small" Tesla deformed much less but this "spannometric" comparison ” makes little sense. The poles seemed different (the one impacted by the Model 3 showed a certain flexibility unlike the one used for the Volvo) and nothing is known about the stresses experienced by the dummies: any evaluation is therefore postponed until after the Crash Test has been carried out officers.