But I'm going to start with the final conclusion before providing the reasoning behind the whys and wherefores. If you want to design a very powerful engine, it's better to use as many cylinders as possible. If you want an efficient engine, it's best to use a configuration with as few cylinders as possible, all for a fixed displacement.

The bore to stroke ratio

The first step for the engineer is to select the unit displacement and the bore to stroke ratio.

But why is an engine with more cylinders better for more power? Let's start with a fixed factor: We are comparing engines with identical total displacement.

When designing an engine, the first thing you have to determine is the diameter of the cylinders and the stroke you want to give to the pistons. You can achieve the same total engine displacement in many ways. For example, you can achieve two and a half litres of displacement between four cylinders (with cylinders of 625 cubic centimetres each), or you can achieve it with ten cylinders (with cylinders of 250 cubic centimetres each).

Determining the unit displacement of each cylinder will lead you to have to choose the bore to stroke ratio you want for each cylinder.

Originally, the typical design of internal combustion engines, after they were invented, was to have a stroke (the total vertical displacement of the piston) considerably longer than the piston bore. But little by little that ratio changed.

Over the years an equal proportion was reached (square engines) and the other extreme was reached, the so-called super-square engines, where the diameter of the piston is greater than the vertical travel of the piston (the stroke).

There are infinite possible combinations between diameter and stroke, but there are extremes that limit all this. On the one hand, the stroke should not exceed 2.2 times the piston diameter (this is the limit for a marine diesel engine, trucks use about 1.3 times the stroke per unit diameter). At the other extreme, the piston diameter should never be more than 2.2 times the stroke in a super-square engine (this is the extreme used by Formula 1).

The advantages of a square or super-square engine are that, for the same unit displacement, it offers more available surface area to place the valves. It also offers less friction to the displacement of the piston in its stroke movement. These two factors help these engines to turn at very high revs.

On the other hand, they have a drawback. By having so much diameter, these square or super-square cylinders offer greater thermal losses (less of the energy of the fuel explosion is converted into crankshaft movement), and also worsens the total time required for combustion (the flame front when the gasoline begins to burn has to travel more distance to complete the burning of the entire mixture). The rod end and rod end bearings also suffer more with these designs.

Long-stroke engines, on the other hand, offer a more compact combustion chamber. This means less thermal losses, higher efficiency, but also more friction (more piston travel), and it is not possible to fit such large valves, which limits the engine's rotational speed.

Ultimately, you have to find a middle ground in engines, dictated by the target customer who is going to use the car. Square or super-square engines are aimed at performance cars, while long-stroke engines fit better in cars where the customer is looking for more torque, more efficiency, and less throttle response.

And now we move on to counting cylinders

The point is that when you are looking for the maximum possible power, you have to go, as we have already explained, to a short-stroke engine, a super-square design engine. This prioritizes the size of the cylinder head, in order to make the cylinder breathe better and reduce friction.

As there is a limitation for the maximum diameter that can be assumed by a piston for reasons of time it takes to burn the mixture on a piston too large unless it is fixed by using several spark plugs per cylinder, to find the maximum power for a given displacement engineers are forced to maintain the relationship between diameter and stroke, without falling into a long stroke engine, not to lose power by using all the available displacement.

This leads them to have to add more cylinders. In the case of the example I have put on the table, the design engineer who wants to make an ultra-powerful 2.5 liter engine, will seek to use the optimal bore to stroke ratio in search of power (1.2 times larger bore than stroke, for commercial engines powered by regular gasoline). Limited by the maximum admissible diameter for a piston (about 92 millimetres approximately), the engineer will opt for cylinders of about half a litre (the standard size, say, assuming a stroke of about 76.6 millimetres), which would lead him to opt for five cylinders as the best solution for a 2.5-litre engine.

With this approach, the design of this supposed engine would already be defined, and focused on power. But what if we change the number of cylinders?

If this engineer wanted to opt for a more powerful engine, the best solution to find that extra power is to make the engine spin faster. Remember, from when we explained what power was (here) and what torque was (here), that power is the result of the engine torque multiplied by the number of turns the crankshaft turns per unit of time (revolutions per minute, for example).

The physical limitation to make an engine turn fast is in the inertia of the elements that move inside it. That is, the limitation for this five-cylinder engine to turn faster than about 8,000 revolutions (by eye) will be in the inertia of the huge piston of 92 millimeters.

There are numbers in engineering that are known as the practical limits at which things start to go wrong. As a general rule, we know that a piston should never exceed a maximum linear velocity of 25 meters per second. If you go beyond that, things start to go wrong, the crankshaft, the connecting rod and the piston start to deform, they can touch the cylinder head, the valves... In short, it's a disaster.

To stay below 25 meters per second, what you have to limit is the amount of stroke that the pistons have. As you can already think, if we reduce the stroke, as the piston diameter is directly related to it (by the figure of 1.2 in our example case), we will have to reduce the unit displacement of each cylinder.

An engine with many cylinders and a large bore in relation to a short stroke offers a high rotational speed, and that means more power.

Therefore, if we reduce the unit displacement, this will lead us to have more cylinders to get up to 2.5 liters. In the end, what do we gain from this? Well, we have all the pistons moving at less than 25 meters per second, but with the engine turning more times every minute.

As we have, in theory, the same torque for the sum of the combustions of all the cylinders than we had before, we get more power for a given displacement.

But be careful, it has a trick. You might think that this is a panacea, but having more cylinders implies other negative aspects, related to efficiency. The more cylinders you have for a given displacement, the more friction and heat loss the engine has, so the torque extracted from that displacement is lower than would be achieved with fewer cylinders. The air and fuel burned is used less well.

Of course, when you are looking for power this is secondary: You don't care if you get less torque per crankshaft rotation, if in exchange you are able to get more crankshaft revolutions per minute. For example, it's better to get only 100 Nm of torque out of the engine but have 800 hp of maximum power, than to have 400 Nm of torque but only 150 hp if you're looking for power.

If we turn the tortilla, and what we are looking for is the maximum possible energy efficiency, what we are interested in is to burn better the gasoline we put on the cylinders. This then implies opting for an engine that has less friction. And less friction means fewer cylinders.

As we have explained above, in addition, long stroke engines, or at least square stroke, and not super-square, offer in this sense a better compromise in efficiency. So you mix the slow revving of the long stroke engine, with the slow revving of the engine with fewer cylinders.

Again, there's a limit to all this. You might think that then the two and a half litre single cylinder engine would be the most efficient engine possible for 2.5 litre displacement, and it's not. The limitations in this regard are in areas such as vibration and derived inertias. The more cylinders an engine has, the more explosions occur per crankshaft revolution, but of lower intensity.

If you divide the explosions that occur per crankshaft revolution into a greater amount, even if they are of less intensity, you get the engine to vibrate less, to be more balanced, to be smoother in its operation.

An engine with too much vibration, besides being coarse and unpleasant to drive, also has a more limited lifespan, and has a more compromised response. In addition, creating engines with few cylinders means creating engines with large pistons, which creates engines with greater inertia, uninterested in changing speed under our orders.

Moral and conclusions

As with almost everything in life, virtue lies in the middle ground, and to find it, there are a series of figures well known to engineers

As everything in this life, being eclectic is the virtue. We must not go to extremes. There are a series of "common knowledge" rules for engineers that eventually end up being applied.

For example, every good engine designer knows that going beyond 92 millimeters for piston diameter is not a good idea. He also knows the maximum linear speed of the piston (25 meters per second), the optimum ratio between bore and stroke for a performance engine (1.2) and that of a torque-focused engine (0.8, for the faint-hearted). Unit cylinder displacements (between 0.4 and 0.5 litres) are also a well-known industry standard.

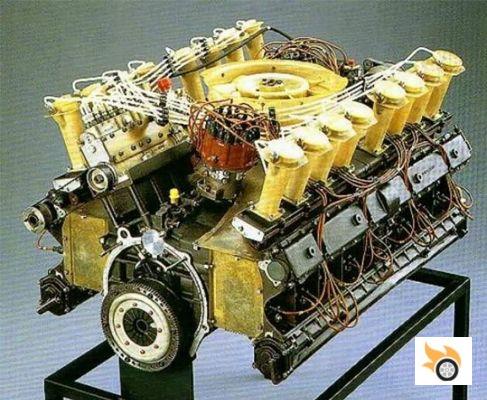

All of this makes the production engines almost always look like "carbon copies" in certain dimensions. Then, when things are taken to extremes such as in racing, you can see true works of engineering, such as the twelve-cylinder three-litre engines, or the six-cylinder engines used by Honda in motorcycles, in search of performance limits, at the expense of fuel consumption.

By the way, if this engineer had to make a performance two and a half litre naturally aspirated engine tomorrow, he'd go for a five-cylinder. And now that you've read the reasons, you would too, wouldn't you?

- Piston speeds of up to 36 metres per second have been achieved in F1.

- The naturally aspirated 2.4 litre V8 F1 engines were around 290 Nm of peak torque, which will give you an idea of how extreme it is to go for maximum revving power by sacrificing torque for faster revs.

- The V8 engine in the Audi RS4 B7 and Audi R8 had a piston speed of 25.7 meters per second.

- That same engine was used as the basis for developing the V10, which in turn served as the basis for creating the five-cylinder two and a half liters of the TT-RS and RS3, which curiously uses the design that we have offered as an example: Five cylinders for 2.5 liters of displacement.

- At the same time, many Audi 0-engines are long-stroke, unlike their rivals

- Honda developed a 125 cubic centimetre racing bike with five cylinders! The RC149 had a nine-ratio gearbox to multiply its starving torque, but it did reach 20,500 rpm!