Introduction

The hydraulic clutch is an essential component in vehicle transmission systems, both automobiles and motorcycles. In this article, we will explore in detail what a hydraulic clutch is, how it works, its key parts, and the various applications in which it is used. We will also cover its definition in a mechanics glossary, the hydraulic clutch kits available on Amazon, and its mechanism in automotive terms.

What is a hydraulic clutch?

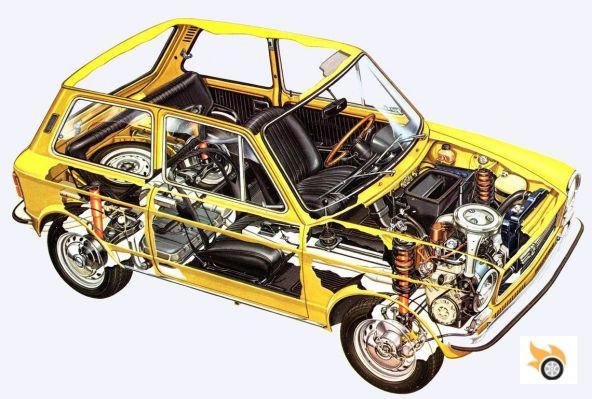

A hydraulic clutch is a device that allows the transfer of energy between the engine and the transmission of a vehicle. Its main function is to transmit the torque generated by the engine to the drive wheels, thus allowing the movement of the vehicle. Unlike traditional mechanical clutches, hydraulic clutches use hydraulic fluid to transmit power.

Hydraulic Clutch Operation

The hydraulic clutch consists of three main components: the torque converter, the pump and the turbine. The torque converter is responsible for transferring energy from the engine to the transmission. It is composed of two elements: the impeller and the rotor. The impeller is connected to and rotates with the engine, while the rotor is connected to the transmission and receives power from the impeller.

The pump is responsible for generating the flow of hydraulic fluid within the clutch. When the engine is running, the impeller rotates and draws the fluid towards the pump, generating a pressure that drives the fluid towards the turbine. The turbine, in turn, receives the fluid and uses it to transmit power to the transmission.

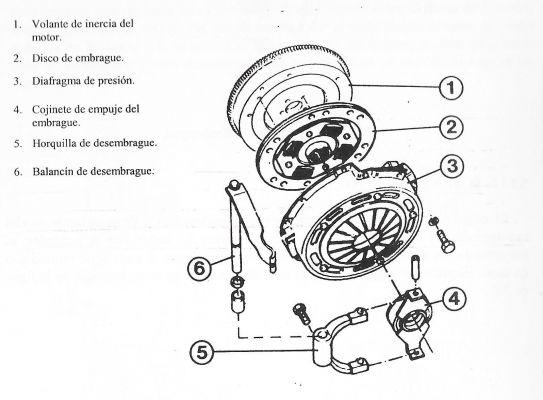

Hydraulic Clutch Key Parts

The hydraulic clutch has several key parts that ensure its correct operation. These include:

1. Impeller

The driver is the part of the clutch that is connected to the engine and rotates with it. Its function is to drag the hydraulic fluid towards the pump, thus generating the necessary flow to transmit the energy.

2. Rotor

The rotor is the part of the clutch that is connected to the transmission and receives power from the impeller. It is responsible for transmitting power to the transmission and eventually to the drive wheels.

3. Bomb

The pump is responsible for generating the flow of hydraulic fluid within the clutch. As the impeller rotates, it draws the fluid into the pump, creating pressure that drives the fluid into the turbine.

4. Turbine

The turbine receives the hydraulic fluid from the pump and uses it to transmit power to the transmission. It is responsible for transferring the engine torque to the drive wheels, thus allowing the movement of the vehicle.

Hydraulic Clutch Applications

The hydraulic clutch is used in a wide variety of applications, both in automobiles and motorcycles. Some of the more common applications include:

1. Automatic transmission vehicles

In automatic transmission vehicles, the hydraulic clutch is essential to allow smooth and seamless gear changes. It allows a smooth transition between the different speeds and ensures optimum engine performance.

2. Pit bikes

Pit bikes, used primarily in motocross and enduro competition, also make use of the hydraulic clutch. This type of clutch provides increased durability and strength, which is crucial in demanding racing environments.

Hydraulic Clutch Definition in a Mechanics Glossary

In a mechanics glossary, a hydraulic clutch is defined as a device that uses hydraulic fluid to transmit torque from the engine to a vehicle's transmission. Unlike traditional mechanical clutches, hydraulic clutches allow for smooth, seamless gear changes.

Hydraulic Clutch Kits Available on Amazon

If you're looking for a hydraulic clutch kit for your vehicle, Amazon offers a wide variety of options. You can find hydraulic clutch kits of different brands and models, adapted to the specific needs of your vehicle. Be sure to read the opinions of other users and compare prices before making your purchase.

Hydraulic clutch mechanism in automotive terms

In automotive terms, the hydraulic clutch mechanism is based on the transfer of energy through a hydraulic fluid. The torque converter, pump, and turbine work together to transmit torque from the engine to the transmission, thus allowing the vehicle to move. This mechanism ensures smooth gear changes and optimal engine performance.

Frequently Asked Questions (FAQs)

1. What is the difference between a hydraulic clutch and a mechanical clutch?

The main difference between a hydraulic clutch and a mechanical clutch lies in the way they transmit power. While a mechanical clutch uses a friction disc and flywheel to transmit torque, a hydraulic clutch uses hydraulic fluid to perform this task. This allows for smoother gear changes and optimum engine performance on vehicles equipped with a hydraulic clutch.

2. What is the useful life of a hydraulic clutch?

The life of a hydraulic clutch can vary depending on proper use and maintenance. Under normal conditions, a hydraulic clutch can last between 80,000 and 120,000 kilometers. However, factors such as clutch quality, driving style, and regular maintenance can influence its durability.

Conclusion

The hydraulic clutch is an essential component in vehicle transmission systems. Its operation based on the use of hydraulic fluid allows smooth gear changes and optimum engine performance. Knowing how it works, the key parts and the various applications it is used in can help you better understand how your vehicle works. If you are looking for a hydraulic clutch kit, remember to check the options available on Amazon and read the opinions of other users before making your purchase. Until next time!