The auxiliary systems of the engine: everything you need to know | pistonknots

The auxiliary systems of the engine: everything you need to know | pistonknots

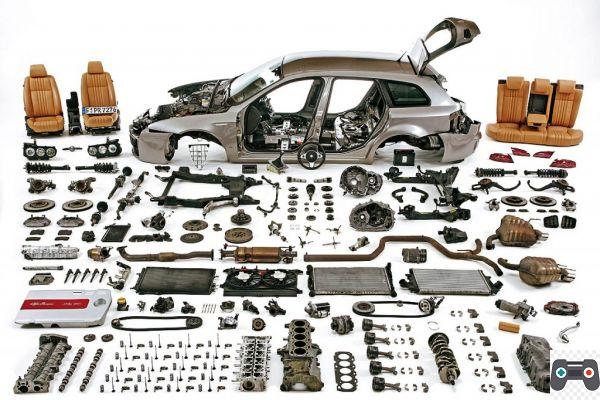

Welcome to Pistonudos, your trusted source for automotive information. In this article, we will cover the different search intents related to auxiliary engine systems. We will explore the auxiliary systems in internal combustion engines, the auxiliary systems of a diesel engine, the 5 auxiliary systems of the engine and what you should know about a car engine. Read on for all the information you need!

Auxiliary systems in internal combustion engines

Auxiliary systems in internal combustion engines are essential components that help the optimal operation of the engine. These systems include the cooling system, lubrication system, ignition system, fuel system, and exhaust system. Each of these systems plays a crucial role in engine performance and durability. Next, we will delve into each of them:

Cooling system

The cooling system is responsible for keeping the engine temperature within proper limits. This is achieved through the use of a coolant that circulates through the engine and absorbs the heat generated during combustion. The coolant is then cooled in the radiator before being recirculated through the engine. A malfunction in the cooling system can cause the engine to overheat, which can result in serious damage.

Lubrication system

The lubrication system ensures that all moving parts of the engine are adequately lubricated to reduce friction and wear. Lubricating oil is pumped through the engine and distributed to the different parts, such as the pistons, connecting rods, and crankshaft. In addition to reducing friction, oil also helps cool engine parts that are exposed to high temperatures. Maintaining an adequate oil level and changing it regularly is essential for the proper functioning of the engine.

Ignition system

The ignition system is responsible for generating the spark necessary for the combustion of fuel in the engine's cylinders. This system consists of the battery, distributor, spark plugs, and ignition wires. When the ignition key is turned, the battery supplies power to the distributor, which in turn sends current to the spark plugs. The spark plugs generate an electrical spark that ignites the air-fuel mixture in the cylinders. A malfunction in the ignition system can lead to difficulty starting the engine or inefficient combustion.

fuel feed system

The fuel supply system is responsible for supplying the proper amount of fuel to the engine. This system includes the fuel tank, fuel pump, fuel filter, and fuel injectors. The fuel pump draws fuel from the tank and sends it to the engine through the injectors. The injectors spray the fuel in the form of fine particles so that it mixes efficiently with the air in the cylinders. A malfunction in the fuel supply system can lead to poor fuel efficiency or a lack of engine power.

Exhaust system

The exhaust system is responsible for removing exhaust gases from the engine and reducing the noise produced during combustion. This system includes the exhaust manifold, catalytic converter, tailpipe, and muffler. Exhaust gases leave the engine through the exhaust manifold and pass through the catalytic converter, where harmful emissions are reduced. The exhaust gases are then expelled through the tailpipe and attenuated in the muffler. A malfunction of the exhaust system can cause an increase in polluting emissions and excessive noise.

Auxiliary systems of a diesel engine

Diesel engines also have auxiliary systems that are similar to those of internal combustion engines, but with some differences. Next, we will analyze the most important auxiliary systems in a diesel engine:

Preheating system

The preheat system is essential in diesel engines, as it helps to heat the air in the cylinders before combustion. This is especially important in cold climates, where diesel fuel can become more viscous and difficult to ignite. The preheating system consists of glow plugs that are responsible for heating the air in the cylinders before combustion. This makes it easier to start the engine in extremely cold conditions.

Fuel injection system

The fuel injection system in diesel engines is different from that in gasoline engines. Instead of using fuel injectors, diesel engines use high-pressure injectors that spray fuel directly into the cylinders. This allows for better fuel atomization and more efficient combustion. In addition, diesel engines often have a high-pressure fuel injection system, which ensures precise and controlled fuel injection.

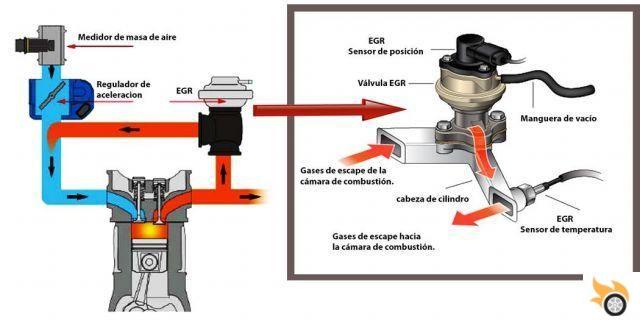

Emission control system

Diesel engines are also equipped with emission control systems to reduce polluting emissions. These systems include the Diesel Particulate Filter (DPF), which traps solid particles in exhaust gases, and the Selective Catalytic Reduction (SCR) system, which reduces oxides of nitrogen (NOx) by injecting a reducing agent. like AdBlue. These systems are essential to comply with environmental regulations and reduce the environmental impact of diesel engines.

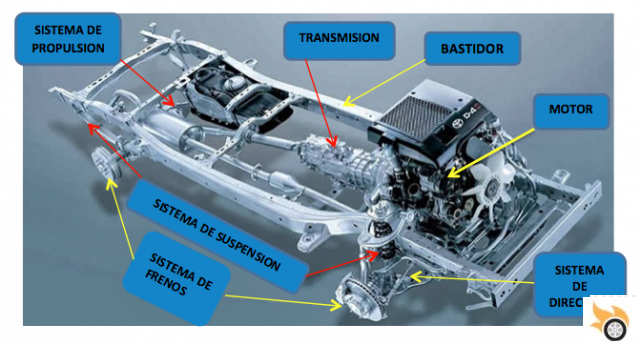

The 5 auxiliary systems of the engine

Regardless of the type of engine, there are five auxiliary systems that are essential for its correct operation. These systems are:

Cooling system

Lubrication system

Ignition system

fuel feed system

Exhaust system

As we mentioned earlier, each of these systems plays a crucial role in engine performance and durability. It is important to make sure that all of these systems are in good condition and working properly to prevent problems and ensure optimal engine operation.

What you should know about a car engine

A car engine is the heart of the vehicle and it is important to understand how it works and how to keep it in good condition. Here are some things you should know about a car engine:

Engine types

There are different types of engines used in automobiles such as gasoline engines, diesel engines, and electric motors. Each type of engine has its own characteristics and advantages, so it is important to choose the type of engine that best suits your needs and preferences.

regular maintenance

Regular maintenance is essential to keep the engine in good condition and prolong its useful life. This includes changing the oil and filters regularly, checking and replacing the spark plugs, checking the coolant level, and keeping the exhaust system in good condition. In addition, it is important to follow the manufacturer's recommendations on