Introduction

Welcome to Pistonudos.com, where we are passionate about the world of engines and everything related to them. In this article, we will focus on providing you with detailed information about the parts and operation of a diesel engine, as well as the main advantages and components. If you are an engine enthusiast or just interested in learning more about them, you've come to the right place!

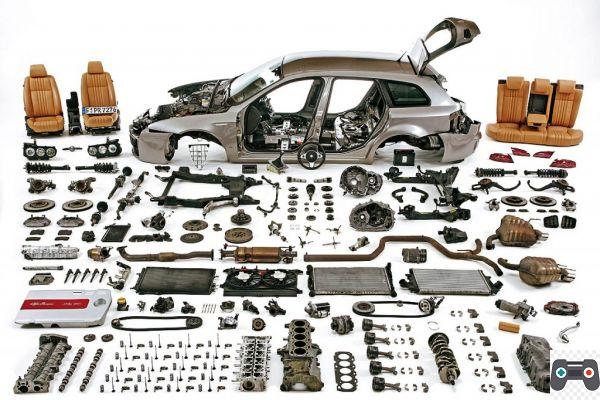

Main parts of the diesel engine

We will begin by knowing the main parts of a diesel engine. These include:

- Engine block: It is the main structure of the engine and houses the cylinders.

- Cylinders: are the spaces where combustion and energy generation occur.

- Pistons: move inside the cylinders and transmit the generated energy.

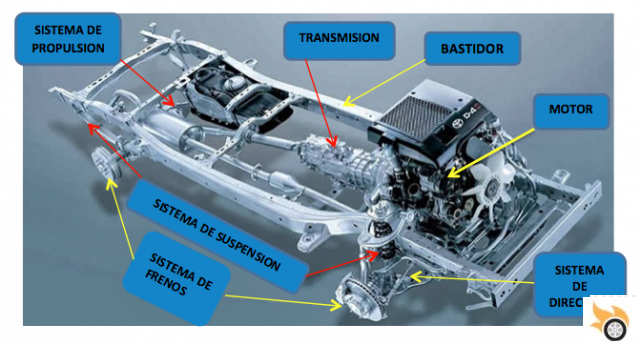

- Connecting Rod - Connects the piston to the crankshaft and converts linear motion into rotary motion.

- Crankshaft: Converts linear motion to rotary motion and transmits power to the transmission system.

- Camshaft: controls the opening and closing of the intake and exhaust valves.

- Valves: Regulate the flow of air and fuel into and out of the cylinders.

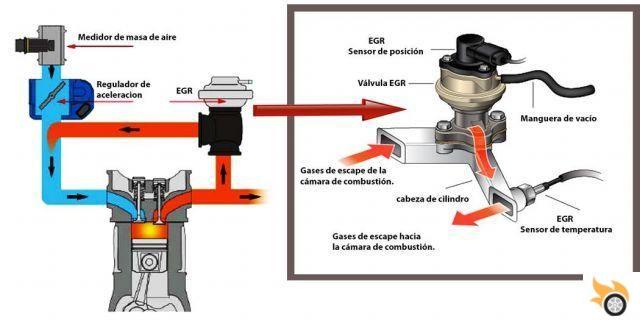

- Fuel injection system: supplies the fuel to the cylinder at the right time.

- Exhaust system: Eliminates exhaust gases produced during combustion.

diesel engine operation

The operation of a diesel engine is based on the four-stroke cycle: intake, compression, combustion and exhaust. Next, we will explain each of these steps:

Admissions

At this stage, the piston moves downward, creating a vacuum in the cylinder. The intake valves open and air is drawn into the cylinder.

Compression

Once the piston reaches its lowest point, it begins to rise and compress the air in the cylinder. This increases the temperature and air pressure.

Combustion

In this step, diesel fuel is injected into the cylinder at high pressure. The heat generated by the compression of the air causes the ignition of the fuel, creating a controlled explosion.

Escape

Finally, the piston moves up again, expelling the exhaust gases through the open exhaust valves. These gases are directed towards the exhaust system and released to the outside.

Advantages of the diesel engine

The diesel engine offers several advantages compared to other types of engines. Some of the main ones are:

- Greater efficiency: Diesel engines are more efficient in terms of fuel consumption and performance.

- Higher Torque – Diesel engines generate more torque, making them ideal for applications that require strength and power.

- Durability – Diesel engines are known for their durability and long life.

- Lower Fire Hazard – Due to its low volatility, diesel fuel has a lower fire hazard compared to gasoline.

Frequently Asked Questions (FAQs)

1. What is the difference between a diesel engine and a gasoline engine?

The main difference between a diesel engine and a gasoline engine lies in the combustion process. While gasoline engines use a spark to ignite the air-fuel mixture, diesel engines compress the air and then inject the fuel, causing ignition.

2. What is the average life of a diesel engine?

The useful life of a diesel engine can vary depending on the maintenance and care that is given to it. However, in general, it is estimated that a well-maintained diesel engine can last between 300,000 and 500,000 kilometers.

Conclusion

In short, the diesel engine is a popular choice due to its efficiency, torque, and durability. Now that you know the main parts and operation of this type of engine, as well as its advantages, you are better prepared to understand and appreciate its importance in the automotive industry. If you have any other questions or comments, feel free to leave them below. We would love to hear your opinion!

Until next time at Pistonudos.com!